CVT (Constant Variable Transmission) Repair

CVT or constant variable transmission used to be limited to recreation vehicles like snowmobiles. In recent years, this type of transmission is starting to become mainstream as well. CVT can be found in some of the popular models from manufacturers such as Audi, GM, Ford and BMW cars.

Unlike the other types of transmission, CVT does not have any gears. Two sets of plates are present in place of gears. These plates move and change the ratios existing between the wheels. These ratios will determine if the vehicle speeds up or slows down. The lowest gear is for starting the vehicle out. The middle gear is used when accelerating and when passing. The highest gear is for fuel-efficient cruising.

How CVT runs

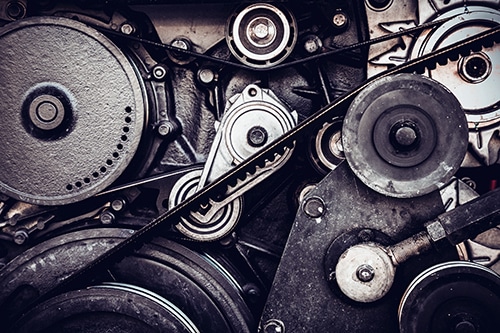

Torque is transmitted between the plates through a belt. Gear or ratio changes proceed smoothly. No interruptions occur. This helps in promoting better fuel economy. There are 2 variable-diameter pulleys in place of the usual gears in other transmission types. These pulleys are cone shaped and arranged to face each other at opposite ends. A metal chain or belt runs between these pulleys. One of the pulleys, the input shaft, is attached to the engine. The output shaft (second pulley) drives the wheels.

Half of the pulley is moveable. When the halves of each pulley are brought closer together, the belt rides the pulley higher. This makes the pulley diameter to become larger.

When a CVT accelerates, the engine adjusts without the usual “kick” experienced when running with automatic or manual transmission. The engine smoothly accelerates (or decelerates) without any sudden jerks or extra movements.

Some people feel that the CVT runs much slower than A/T because of this. However, most CVTs on cars today can easily outrun automatic transmissions. One of the concerns about CVT is the sound of the engine. Stepping hard on the accelerator will cause the engine to race. The sound is similar to the sound of a failing automatic transmission or a slipping clutch. This sound, however, is normal for a CVT. This sound is an indication that the transmission adjusts the engine speed for optimal power during acceleration. This can be quite disconcerting for those used with automatic transmissions, though, fearing that something is seriously wrong with the car.

Maintenance care for CVT

Some care tips for longer belt life include:

- Avoid overloading the vehicle. This can lead to excess heat or slippage to the belt, especially when driving uphill.

- Stop the vehicle immediately when smell of burnt rubber is observed.

- Remove the driveshaft or chain if cruising or coasting downhill for several kilometers.

- Never use the throttle to keep the vehicle from rolling backwards. Use the brakes instead. Release the brake as son as pressing down on the throttle.

- Regularly check the edge of the belt. Immediately cut off any frays, no matter how small.

- Take extra care when driving through yearling trees, tall bushes or long grasses. If any debris gets sucked into the CVT, it will damage the belt.

- Avoid driving through a snow or sand storm. If inevitable, wipe down the inner surfaces immediately after. Park the car on level ground and turn off the engine.

- Apply the wheel chocks then start wiping down the inner surface.

- Never allow diesel, gasoline or engine oil to drip on the belt.

A CVT has a hydraulics system. This manages the high amount of pressure on the pulleys. To keep the system working well, the fluid should be regularly changed. Check with the manufacturer for schedule of fluid change.